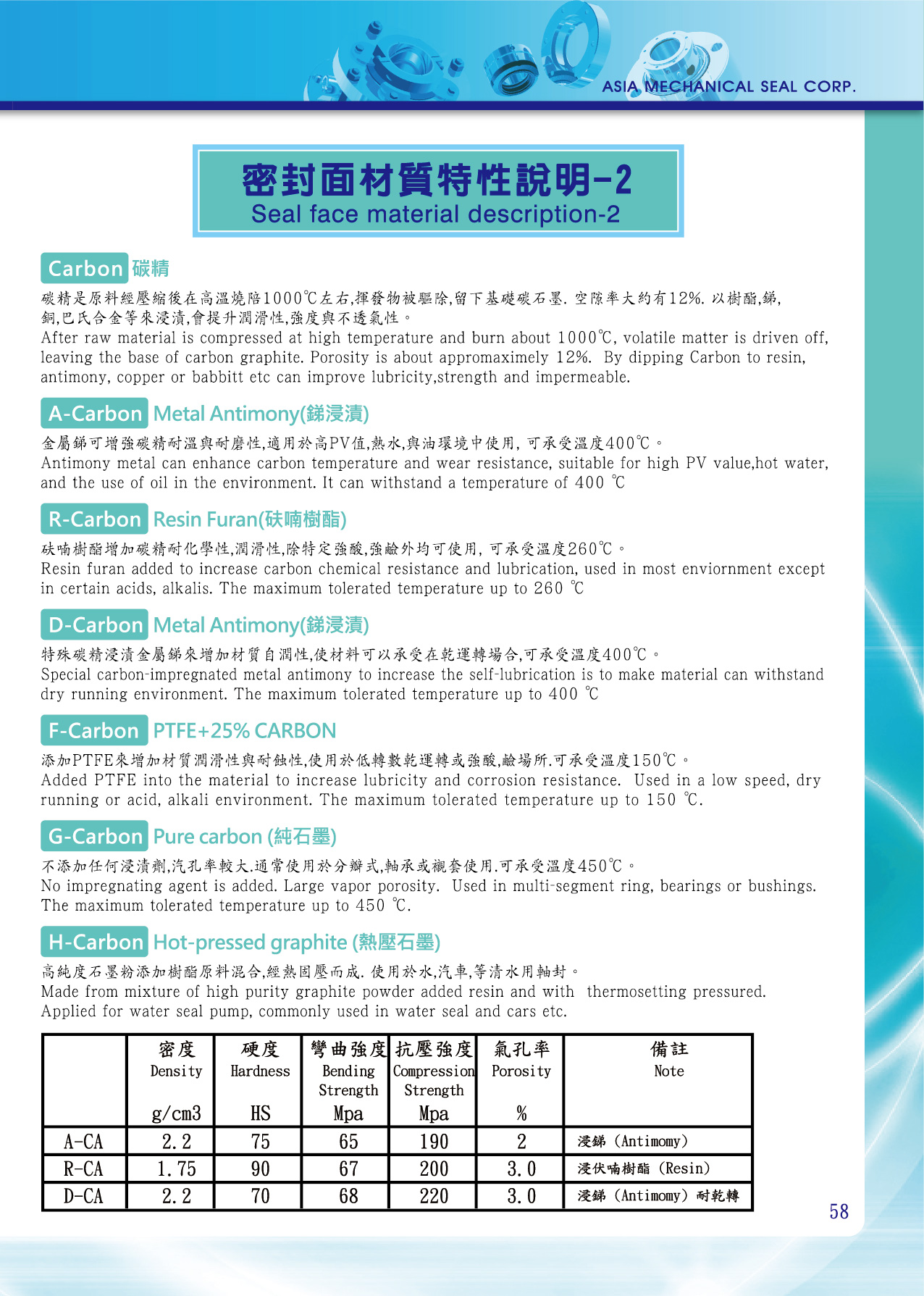

Seal face materialCARBON

The CARBON raw material is compressed and then sintered at a high temperature of about 1000 degrees. After the residue is volatilized, the basic graphite is left behind. There is about 12% of the gap. The gap is filled with resin, antimony and babbitt alloy. In order to achieve airtightness.